Molecular Microbiology and Genetics

- Professor

- INUI Msayuki

- Associate Professor

- KOGURE Takahisa

- Labs HP

- https://www.rite.or.jp/bio/en/naist/

Outline of Research and Education

In recent years, the trend towards carbon neutrality and bioeconomy has been accelerating worldwide, aiming to overcome global warming and the depletion of energy resources, which have become major social issues. Against this background, Molecular Microbiology and Genetics Laboratory has been consistently working on research and development of sustainable, environmentally-friendly bioprocesses that efficiently produce biofuels and green chemicals from renewable biomass raw materials utilizing the "fermentation ability of microorganisms." Through the exploration of microbial functions that can effectively utilize renewable biomass resources and the creation of "smart cells" that maximize microbial production capabilities, we are working on research and development aimed at realizing a decarbonized, recycling-oriented society.

Major Research Topics

New developments in biomanufacturing

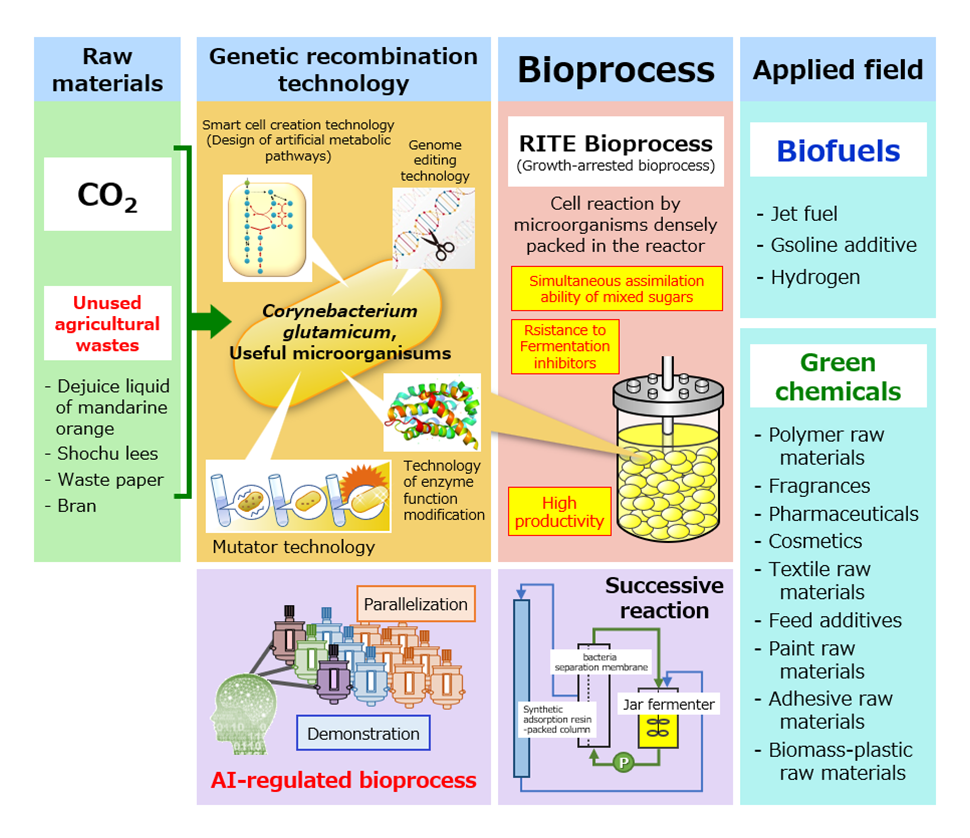

Biomanufacturing is a concept that uses bioprocesses to produce chemicals and fuels from biomass, a renewable resource, and is expected to play a major role in building a decarbonized and recycling-oriented society. In the Molecular Microbiology and Genetics Laboratory, we are working on developing technology to produce biofuels and green chemicals from unused agricultural waste and CO2 as raw materials by applying a highly efficient bioprocess named as " RITE Bioprocess (Growth-arrested bioprocess)" that we developed using Corynebacterium glutamicum, which is a bacterium widely used in the industrial production of amino acids (Fig. 1). In creating microbial strains that enable highly efficient production of targeted compounds, we apply synthetic biology, which aims to design and optimize gene sequences, enzymes, and (artificial) metabolic pathways by making full use of smart cell creation technology including AI and digital technology and omics analysis technology, which have made remarkable progress in recent years. We are also working on optimizing bioprocesses using AI-control and developing engineering production methods such as continuous cell reactions (Fig. 1).

Production of biofuels and green chemicals

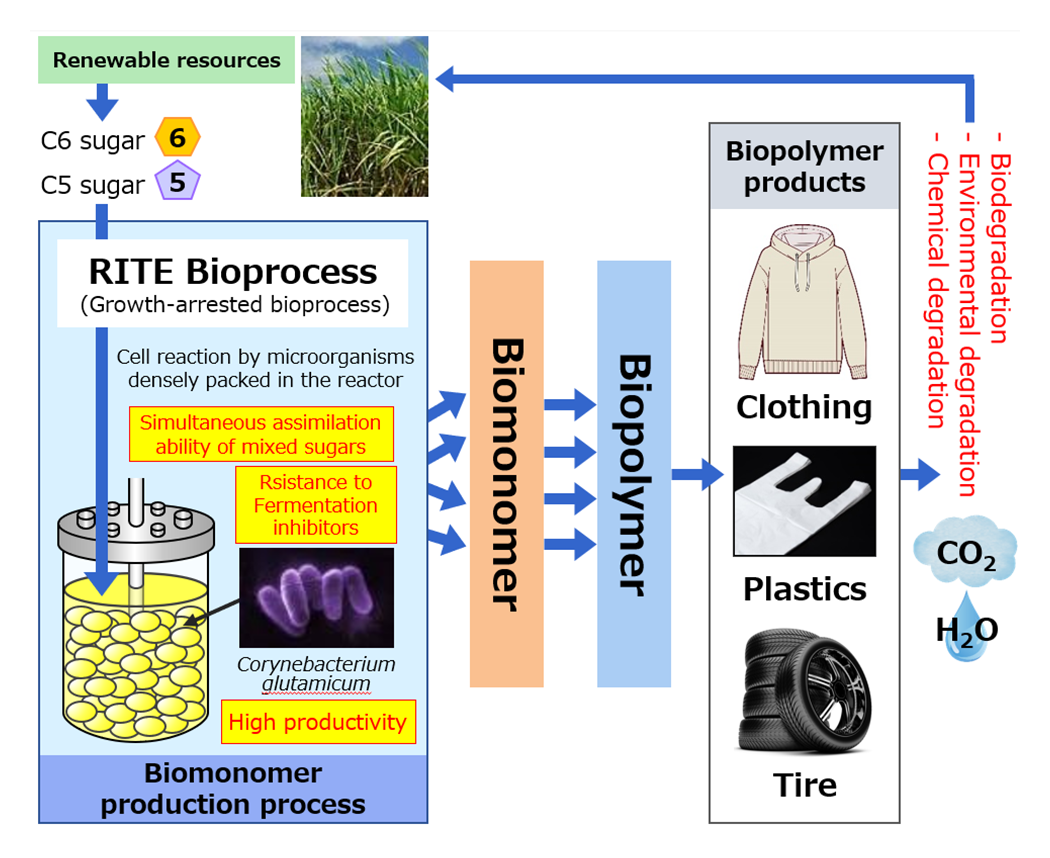

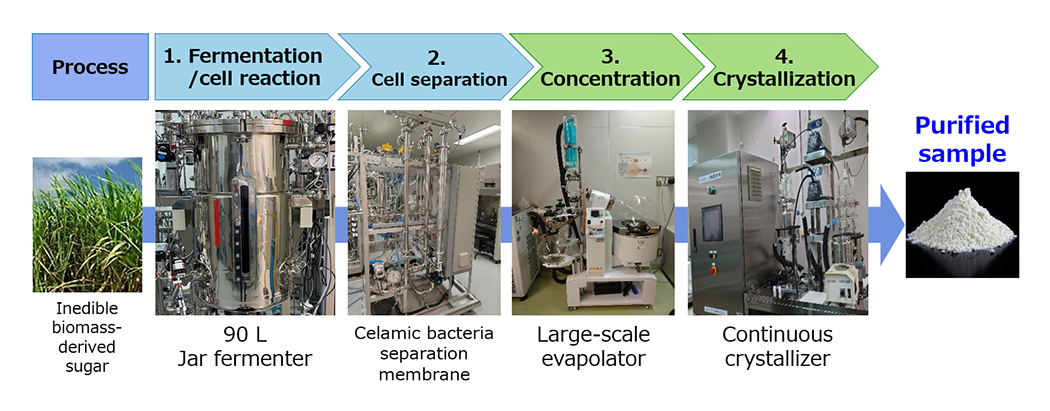

In the field of biofuels, we have established the basic technology for producing bioethanol from non-food biomass, and are currently working on the development of production technology for biohydrogen, biobutanol, and biojet fuel materials, which are expected as the next-generation fuels. In addition, as for green chemicals, we are developing production technology for a wide range of target compounds, including organic acids, alcohols, and isoprene (Fig. 2), which are raw materials for various general-purpose polymers, as well as various aromatic compounds that are useful in the fields of high-performance polymers, medicines, cosmetics, fragrances, and functional food ingredients. We have established a bench-scale integrated bioproduction system from fermentation using developed strains to product purification processes, promoting commercialization of microbial production of various target compounds (Fig. 2). Recently, we have also participated in various national projects and are focusing on the creation of innovative biomaterials, such as marine biodegradable biopolymers with a decomposition switch mechanism, and "biomanufacturing" using CO2 directly as a raw material.

References

- Y. Tanaka Y. et al., FEBS J, 291, 4489-4500, 2024

- Shimizu T. et al., Appl Microbiol Biotechnol, 108, 58, 1-11, 2024

- Nakamichi Y. et al., Acta Crystallogr D Struct Biol, D79, 895-908, 2023

- Teramoto H. et al., Int J Hydrog Energy, 47, 29219-29229, 2022

- Teramoto H. et al., Int J Hydrog Energy, 47, 22010-22021, 2022

- Shimizu T. et al., Appl Environ Microbiol, 88, e0050722, 2022

- Toyoda K. et al., Microorganisms, 10, 1002, 2022

- Tanaka Y. et al., J Bacteriol, 204, e0005322, 2022

- Nakazawa S. et al., ACS Synth Biol, 10, 2308-2317, 2021

- Toyoda K. et al., Microorganisms, 9, 550, 2021

- Jojima T. et al., Biotechnol Biofuels, 14, 45, 2021

- Kogure T. et al., Metab Eng, 65, 232-242, 2021

- Uchikura H. et al., Appl Microbiol Biotechnol, 104, 6719-6729, 2020

- Hasegawa S. et al., Metab Eng, 59, 24-35, 2020

- Shimizu T. et al., Appl Microbiol Biotechnol, 103, 9739-9749, 2019

- Han S.O. et al., Biotechnol J, 14, e1900160, 2019

- Tsuge Y. et al., Appl Microbiol Biotechnol, 103, 3381-3391, 2019

- Oide S. et al., Enzyme Microb Technol, 125, 13-20, 2019

- Shimizu T. et al., Appl Environ Microbiol, 85, e01873-18, 2019

- Tsuge Y. et al., J Biosci Bioeng, 127, 288-293, 2019

NAIST Edge BIO

NAIST Edge BIO